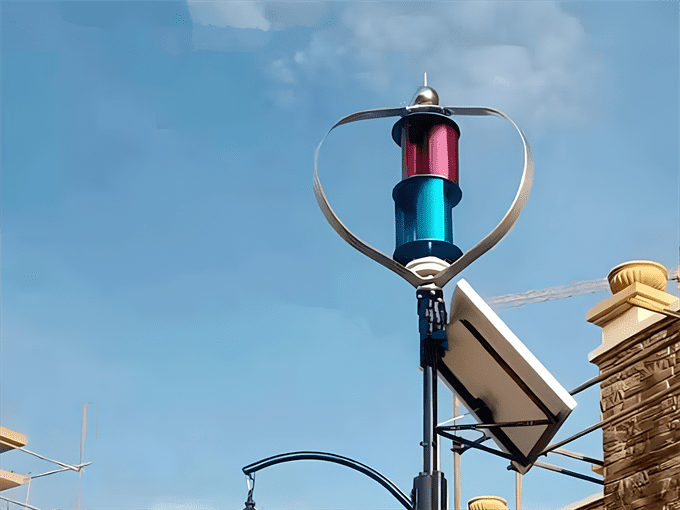

As a clean and renewable energy source, Residential Wind Turbines has been widely used around the world. However, as a large mechanical equipment, wind turbines need regular maintenance to ensure their safe, efficient and stable operation.

1. Residential Wind Turbines: the importance of maintenance

The maintenance of wind turbines is essential to ensure their safe, stable and efficient operation. Regular maintenance can:

Improve power generation efficiency:

Regular maintenance can ensure that all components of wind turbines are in the best working condition, improve power generation efficiency and reduce operating costs.

Extend equipment life:

Regular maintenance can promptly detect and solve equipment failures, avoid equipment damage caused by failures, extend equipment life and reduce replacement costs.

Ensure safe operation:

Regular maintenance can ensure the safe operation of wind turbines and avoid casualties and property losses caused by equipment failures.

Improve return on investment:

Regular maintenance can improve the power generation efficiency and equipment life of wind turbines, thereby improving the return on investment.

2. Residential Wind Turbines: Common maintenance content

The maintenance content of wind turbines mainly includes the following aspects:

a. Blade inspection and maintenance:

Blades are key components of wind turbines and need to be inspected and maintained regularly to ensure their normal operation.

Blade cleaning:

Clean dust, bird droppings and other dirt on the blades regularly to avoid affecting the efficiency of wind energy capture.

Blade damage inspection:

Check whether the blades have cracks, breakage and other damages, and repair or replace them in time.

Blade balance inspection:

Check whether the blades are balanced to avoid vibration caused by imbalance and affect the operation of the equipment.

Blade lightning protection measures:

Check whether the blade lightning protection measures are complete to avoid damage to the blades caused by lightning strikes.

b. Cabin inspection and maintenance:

The cabin is the core component of the wind turbine and needs to be inspected and maintained regularly to ensure its normal operation.

Cabin cleaning:

Clean dust, oil stains, etc. inside the cabin regularly to avoid affecting the operation of the equipment.

Cabin component inspection:

Check whether various components in the cabin, such as gearboxes, generators, control systems, etc., are working properly and repair or replace them in time.

Cabin ventilation inspection:

Check whether the cabin ventilation is good to avoid equipment damage caused by excessive temperature.

Cabin moisture-proof measures:

Check whether the cabin moisture-proof measures are complete to avoid equipment damage caused by moisture.

c. Tower inspection and maintenance:

The tower is the supporting structure of the wind turbine and needs to be inspected and maintained regularly to ensure its safety and stability.

Tower corrosion inspection:

Check whether the tower is corroded and carry out anti-corrosion treatment in time.

Tower welding inspection:

Check whether the tower welding is firm and repair or replace it in time.

Tower foundation inspection:

Check whether the tower foundation is stable and reinforce or repair it in time.

Tower lightning protection measures:

Check whether the tower lightning protection measures are complete to avoid damage to the tower caused by lightning strikes.

d. Control system inspection and maintenance:

The control system is the brain of the wind turbine and needs to be inspected and maintained regularly to ensure its normal operation.

Control system software upgrade:

Update the control system software regularly to improve equipment performance and safety.

Control system parameter setting:

Check whether the control system parameter setting is reasonable and adjust and optimize it.

Control system fault diagnosis:

Check whether the control system has any faults and repair or replace it in time.

Control system backup:

Back up the control system data regularly to avoid the equipment from not being able to operate normally due to data loss.

e. Generator inspection and maintenance:

The generator is the core component of the wind turbine and needs to be inspected and maintained regularly to ensure its normal operation.

Generator performance test:

Perform performance tests on the generator regularly to ensure its power generation efficiency and stability.

Generator insulation inspection:

Check whether the insulation of the generator is good to avoid equipment damage due to poor insulation.

Generator cooling system inspection:

Check whether the generator cooling system is working properly to avoid equipment damage due to excessive temperature.

Generator lubrication system inspection:

Check whether the generator lubrication system is working properly to avoid equipment damage due to poor lubrication.

3. Residential Wind Turbines: common methods of maintenance

The maintenance methods of wind turbines mainly include the following:

a. Regular inspection:

Regularly inspect the wind turbine, check the operating status of the equipment, and deal with problems in a timely manner.

Inspection frequency:

The inspection frequency can be adjusted according to the equipment operation and environmental conditions. It is generally recommended to conduct an inspection once a day.

Inspection content:

The inspection content includes observing the equipment operation, checking the equipment appearance, listening to the equipment operation sound, measuring the equipment operation parameters, etc.

Inspection record:

Each inspection needs to be recorded, recording the inspection time, inspection personnel, inspection content, problems found and other information.

b. Regular maintenance:

Regularly maintain the wind turbine, clean, inspect, adjust, and repair the equipment.

Maintenance frequency:

The maintenance frequency can be adjusted according to the equipment operation and environmental conditions. It is generally recommended to perform maintenance once a quarter.

Maintenance content:

The maintenance content includes cleaning, inspecting, lubricating, adjusting, and replacing parts of the equipment.

Maintenance record:

Each maintenance needs to be recorded, recording the maintenance time, maintenance personnel, maintenance content, replacement parts and other information.

c. Fault handling:

When a wind turbine fails, it is necessary to handle the fault in a timely manner to avoid the expansion of the fault and affect the operation of the equipment.

Fault diagnosis:

First, it is necessary to perform fault diagnosis, determine the cause of the fault, and formulate corresponding treatment plans.

Fault handling:

Perform fault handling according to the cause of the fault, such as replacing parts, repairing equipment, etc.

Fault records:

Each fault handling needs to be recorded, recording the fault time, fault cause, fault handling method, handling results and other information.

4. Residential Wind Turbines: maintenance precautions

The following points should be noted in the maintenance of wind turbines:

a. Safety first:

Maintenance work must take safety as the primary principle to ensure the safety of personnel and equipment.

Safety training:

Maintenance personnel need to receive safety training, understand safety operating procedures, and strictly abide by safety operating procedures.

Safety measures: When performing maintenance work, appropriate safety measures need to be taken, such as wearing safety helmets, safety belts, safety shoes, etc.

Safety inspection:

Before performing maintenance work, a safety inspection is required to ensure that the equipment is in a safe state.

b. Professional specifications:

Maintenance work needs to be carried out strictly in accordance with professional specifications to ensure the quality of maintenance.

Standard specifications:

Maintenance work needs to follow relevant standard specifications, such as the maintenance manual provided by the manufacturer of the wind turbine.

Professional skills: Maintenance personnel need to have professional skills and be proficient in the structure, working principle, maintenance methods, etc. of the equipment.

Tools and equipment: Maintenance work requires the use of professional tools and equipment to ensure the quality of maintenance.

c. Complete records:

Maintenance work needs to be fully recorded to facilitate subsequent maintenance work and fault analysis.

Record content:

The record content includes maintenance time, maintenance personnel, maintenance content, replacement parts and other information.

Record format:

The record format needs to be unified for easy query and statistics.

Record preservation:

The records need to be properly preserved for future reference.

d. Prevention first:

Maintenance work should be prevention first, and regular inspections and maintenance should be carried out to avoid faults.

Regular cleaning:

Clean the equipment regularly to avoid accumulation of dirt such as dust and oil, which will affect the operation of the equipment.

Regular lubrication:

Lubricate the equipment regularly to avoid equipment damage due to poor lubrication.

Regular adjustment:

Regularly adjust the equipment to ensure that the equipment is in the best working condition.

5. Residential Wind Turbines: Future trends in maintenance

In the future, with the advancement of technology, the maintenance of wind turbines will be more intelligent, automated, and digital.

a. Intelligent maintenance:

For example, monitor the operating status of the equipment through sensors, predict and warn of faults, and perform maintenance in time to avoid faults.

b. Automated maintenance:

For example, use robots to clean, inspect, and repair equipment to improve maintenance efficiency and safety.

c. Digital maintenance:

For example, establish a digital model of wind turbines, perform virtual maintenance and fault simulation, and improve maintenance efficiency and accuracy.

Summary:

The maintenance of wind turbines is the key to ensuring their safe, efficient, and stable operation. Regular maintenance can improve power generation efficiency, extend equipment life, ensure safe operation, and increase return on investment.