Building Your Own Vertical Axis Wind Turbine

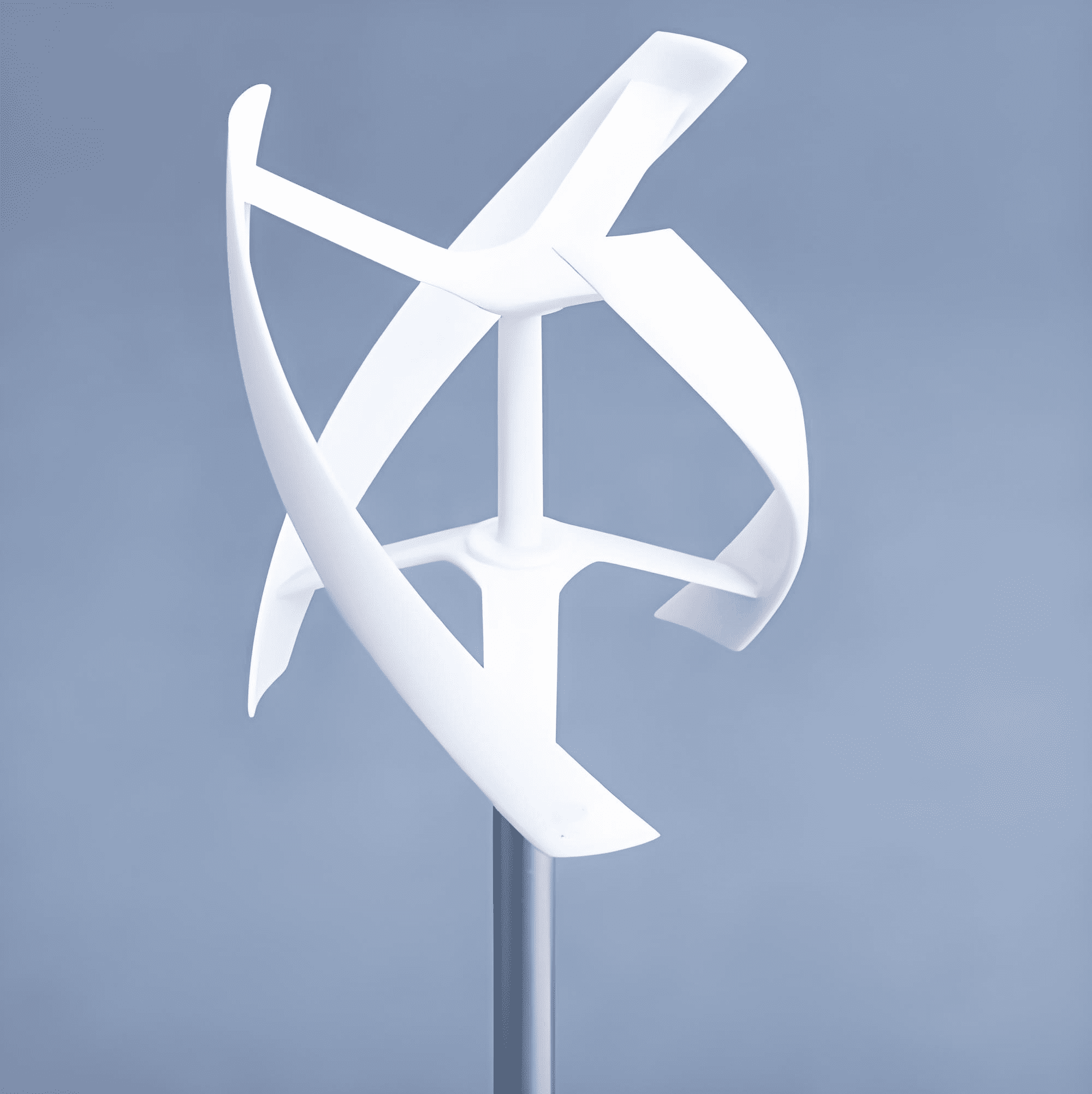

As a renewable energy source, wind power has attracted more and more attention and favor. Among many wind power technologies, vertical axis wind turbines have attracted much attention due to their unique design. Unlike traditional horizontal-axis wind turbines, vertical-axis wind turbines can capture wind power from all directions and have a simpler structure and lower maintenance costs.

For those who have DIY hobbies, making your own vertical axis wind turbine is undoubtedly a good choice. Not only can you experience the fun of making in person, but you can also install and use it at home, adding green power to your life. Let me introduce to you how to make a vertical axis wind turbine by yourself.

To make a vertical axis wind turbine, we need to prepare the following materials:

Permanent magnet generator (power depends on demand, usually between 100-500W)

Blades (can be made of PVC pipes or wooden boards, 3-5 pieces is better)

Bracket (can be made of metal pipe or wood)

Bearings (to support the blade shaft)

Wire (for connecting the generator to the battery)

Battery (used to store electricity generated by the generator)

Other auxiliary tools (saw, drill, glue, etc.)

Vertical axis wind turbine production steps

1. Make the leaves

Blades are the core components of vertical axis wind turbines, and their design directly affects the performance of the generator. We can use PVC pipes or wooden boards to make blades. The specific steps are as follows:

Measure the length and width of the PVC pipe or wooden board. Generally, 3-5 blades are suitable, each blade is 50-100cm long and 10-20cm wide.Use a saw to cut the PVC pipe or board to the desired size. Apply waterproof glue to the surface of the blade to increase weather resistance. Drill holes in the top of the blade for mounting to the bracket.

2. Make the stand

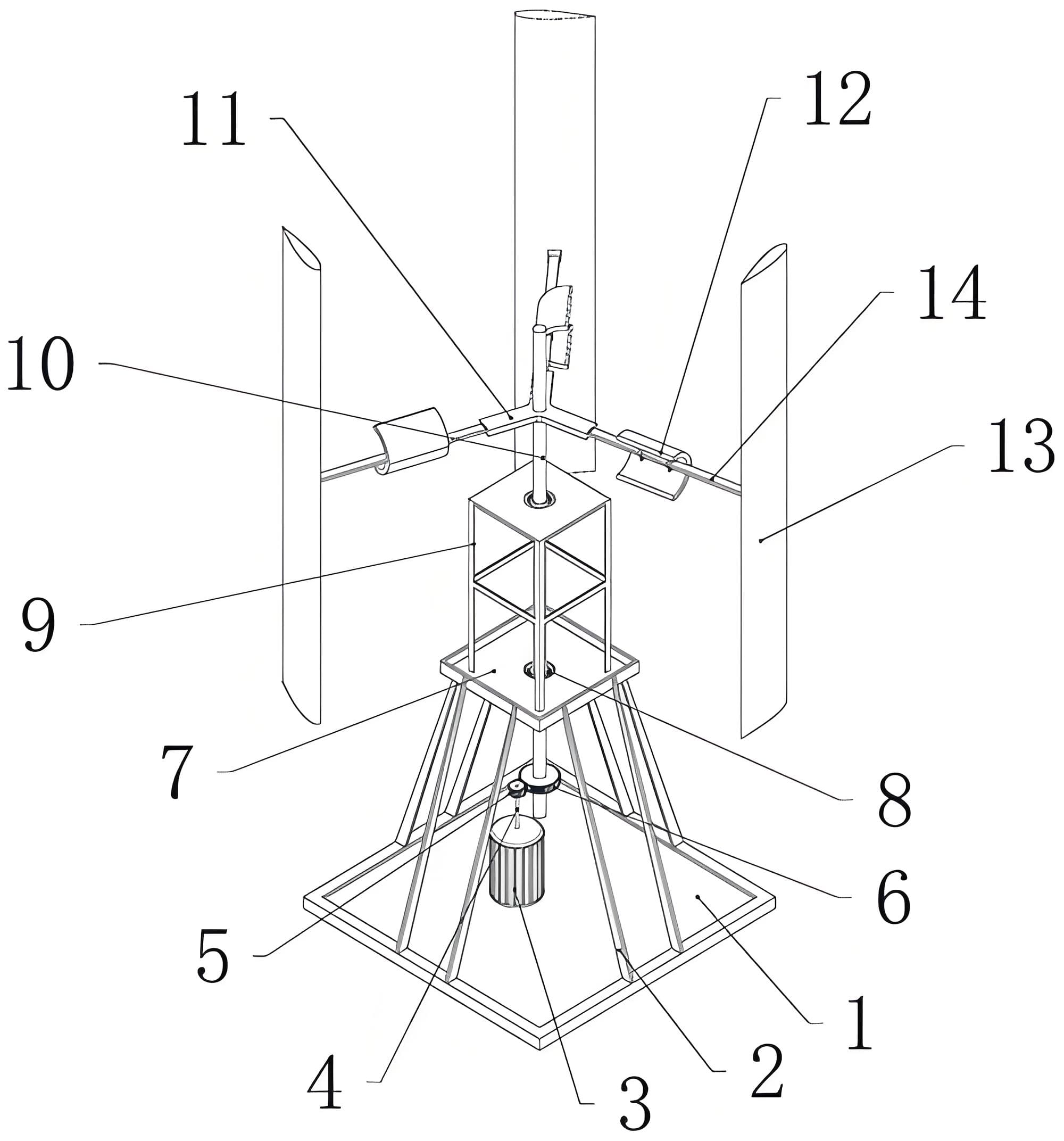

The function of the bracket is to fix the blades and generator to ensure that the entire system can operate stably. We can use metal pipes or wood to make brackets, the specific steps are as follows:

Measure the height and width of the bracket, depending on the actual situation and blade size. Use metal tubing or wood cut to the desired length. Use a welder or screws to connect the components to form the main structure of the bracket. Drill holes on the top of the bracket to install the bearing and generator.

3. Install the generator

The generator is the core component of the entire vertical axis wind power generation system and is responsible for converting wind power into electrical energy. We need to install the generator on the bracket and connect it to the blades. The specific steps are as follows:

Install the generator to the top of the bracket and secure it with screws. Make sure the generator shaft is aligned with the hole in the top of the bracket.Install bearings on the generator shaft to reduce friction and ensure smooth rotation. Align the center hole of the blade with the generator shaft and secure it in place with screws. Make sure the blades can rotate freely.

Vertical axis wind turbine circuit connection

Connect the generator’s output terminals to the battery’s positive and negative terminals, and connect them with wires. A controller can be added to the circuit to regulate the output voltage and current of the generator to protect the battery. If you need to power household appliances, you can add an inverter between the battery and the household appliances to convert DC power into AC power.

Vertical axis wind turbine debugging and optimization

Install the entire system in an open, well-ventilated area and try to avoid obstructions. Start the system and observe whether the blades can rotate smoothly and the generator can generate electricity normally. The angle and number of blades can be adjusted to obtain the best power generation effect. Regularly check the connection status of each component to ensure the stable operation of the system.

Vertical axis wind turbine precautions

Safety first, please be careful when operating to avoid personal injury. Choose the right materials and parts to ensure system reliability and durability. Regular maintenance ensures long-term stable operation of the system. According to the actual situation and needs, appropriately adjust the system parameters and configuration.

Through these steps, I believe you will be able to successfully build a vertical axis wind turbine and add green power to your life. If you encounter any problems during the production process, please feel free to communicate with me at any time. Good luck with your production!

Learn More:A critical review of vertical axis wind turbines for urban applications