Introduction

Wind power generation, as a clean and renewable energy source, is developing rapidly around the world. As a key component of the wind power system, the choice of materials for wind turbine blades directly affects the efficiency, cost and environmental impact of the wind power system. This article will explore the current status, challenges and future development direction of wind turbine blade materials.

1. The role and importance of wind turbine blades

1.1 Basic functions of wind turbine blades

The main function of wind turbine blades is to convert wind energy into mechanical energy, and then convert mechanical energy into electrical energy through generators. The design and material selection of blades have a vital impact on the performance of wind turbines. Blades need to have high strength, light weight, fatigue resistance and corrosion resistance to ensure long-term stable operation under various climatic conditions.

1.2 Importance of wind turbine blade materials

The choice of materials determines the performance, cost and life of blades. At present, composite materials have become the mainstream choice for wind turbine blades due to their excellent mechanical properties and lightweight advantages. However, with the continuous advancement of wind power generation technology, the requirements for blade materials are also increasing, and it is necessary to find higher performance and more sustainable materials.

2. Current status of wind turbine blade materials

2.1 Glass fiber composites

Glass fiber composites are currently the most commonly used wind turbine blade materials. It has the advantages of low cost, high strength, and corrosion resistance. However, glass fiber composites have certain limitations in fatigue performance and recycling.

2.2 Carbon fiber composites

Carbon fiber composites have higher strength and stiffness, while being lighter, so they are increasingly used in large wind turbine blades. Although carbon fiber composites are more expensive, their superior performance makes them have broad application prospects in super-large wind turbine blades.

2.3 Resin-based composites

Resin-based composites further improve the comprehensive performance of the material by combining glass fiber or carbon fiber with resin. Common resin bases include epoxy resins and polyester resins, which can optimize material properties by adjusting the formula while improving material strength and durability.

3. Exploration of new wind turbine blade materials

3.1 Polymer materials

Polymer materials, such as thermoplastic resins and thermosetting resins, are becoming a new research hotspot. Thermoplastic resins have the advantage of being recyclable, while thermosetting resins have higher strength and heat resistance. The performance of wind turbine blades can be further improved by optimizing the formulation and processing technology of polymer materials.

3.2 Self-repairing materials

Self-repairing materials can automatically repair themselves when damaged through built-in repair mechanisms, thereby extending the service life of blades. The research on this type of material is still in its early stages, but its potential application prospects are very broad.

3.3 Nanocomposites

Nanocomposites can significantly improve the strength, stiffness and wear resistance of materials by introducing nanoparticles into the matrix. The development and application of nanocomposites are expected to provide higher performance and longer service life for wind turbine blades.

4. Challenges of wind turbine blade materials

4.1 Cost control

Although new materials have significantly improved performance, their high cost is the main obstacle to large-scale application. In the future, it is necessary to reduce material costs through technological innovation and economies of scale to make it more economically competitive.

4.2 Environmental impact

Although wind power generation is a clean energy source, the production and waste treatment of blade materials still have a certain impact on the environment. Improving the recyclability of materials and reducing carbon emissions in the production process are important directions for future development.

4.3 Technology maturity

Many new materials are still in the laboratory research stage and are still a long way from large-scale commercial applications. Further research and testing are needed to verify their reliability and stability in practical applications.

5. Future development direction of wind turbine blade materials

5.1 Recyclable materials

In the future, the development of recyclable wind turbine blade materials will be an important way to solve environmental problems. Recyclable materials such as thermoplastic resins and natural fiber composites are expected to be widely used in the future.

5.2 Smart materials

Smart materials can monitor and repair blade damage in real time by embedding sensors and self-repair mechanisms, thereby improving the operating reliability and life of wind turbines. The research and application of such materials will bring revolutionary changes to wind power generation technology.

5.3 Material optimization design

Through computer simulation and optimization design, the best combination can be achieved in material selection and structural design, and the comprehensive performance and service life of the material can be improved. Multidisciplinary cross-disciplinary research will further promote the development of wind turbine blade materials.

6. Summary

The development of wind turbine blade materials is crucial to wind power generation technology. The main development directions include: lightweight, high-performance composite materials, smart materials and recyclable materials, interdisciplinary and international cooperative research, sustainable development and environmental friendliness. Leading companies such as Vestas, Siemens Gamesa and GE are actively innovating. With broad market prospects and strong policy support. In the future, we will continue to promote the development of the wind power industry and contribute to the global clean energy transformation.

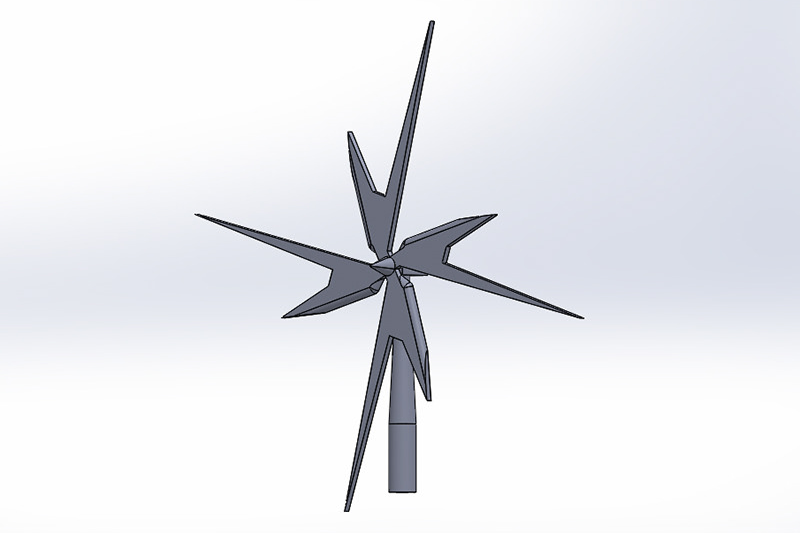

wind turbine blades:What is a wind turbine and how does it work?