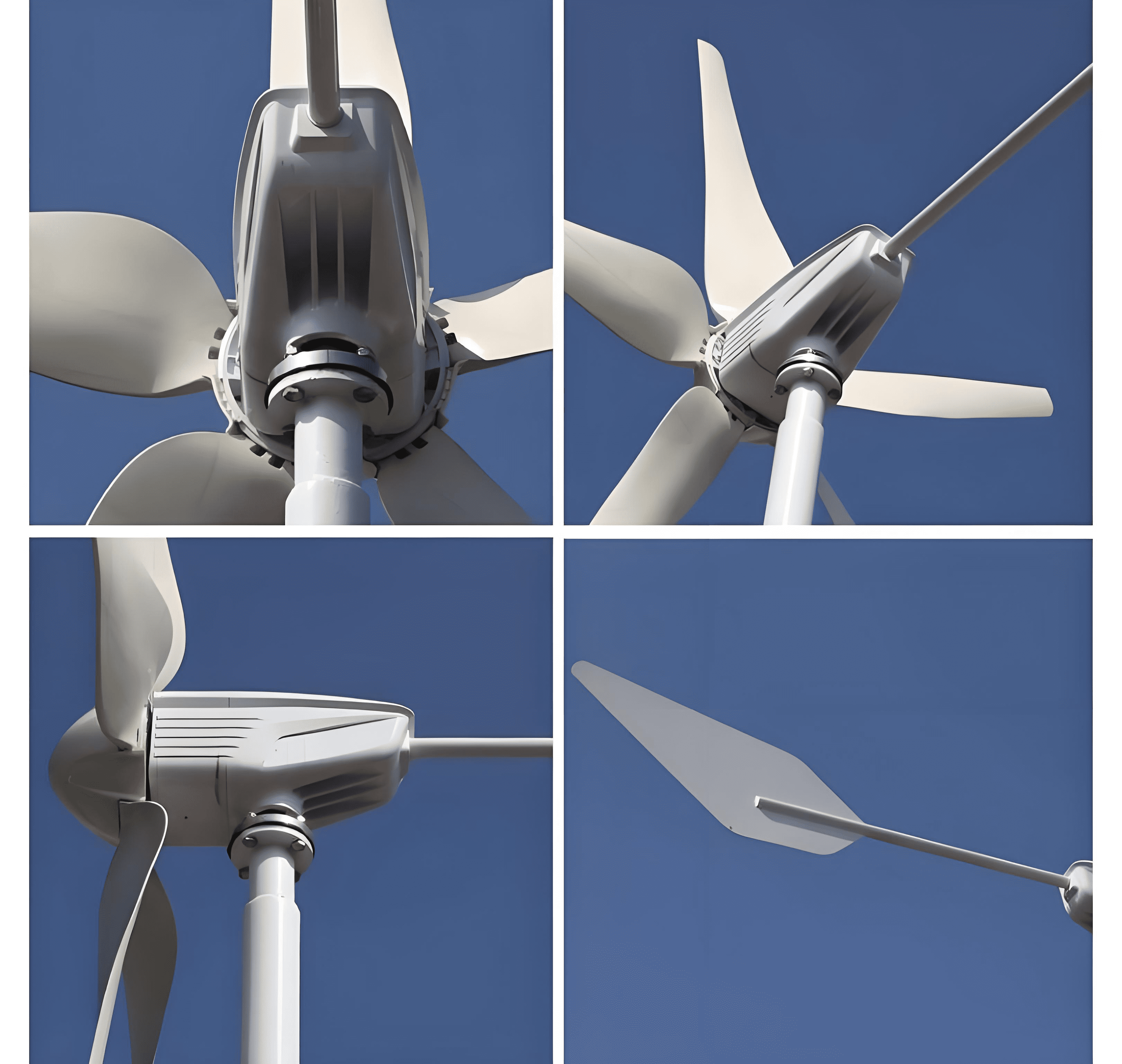

The relationship between the number of blades and power generation efficiency

The number of blades of a wind turbine is one of the key factors affecting its power generation efficiency. Usually, the number of blades of wind turbines has 1, 2, 3 or more design options. So, why do wind turbines generally adopt a three-blade design? What are the engineering and technical considerations involved?

1. Advantages and Disadvantages of Single Blade Design

The single-blade design is the simplest and most straightforward solution, but it has some obvious disadvantages:

The single blade design has poor stability, is easily affected by wind changes, and has low power generation efficiency.

The load distribution of the single blade design is uneven, which can easily lead to insufficient structural strength and prone to failure.

The single-blade design has weak self-balancing ability and is prone to vibration problems.

Therefore, the single blade design is not suitable for large wind turbine applications.

2. Advantages and disadvantages of double blade design

Compared with single blade design, double blade design has certain advantages:

The double-blade design has stronger stability and self-balancing capabilities, which is beneficial to improving power generation efficiency.

The double-blade design has a more even load distribution, higher structural strength, and is more reliable.

The two-blade design has relatively low manufacturing costs and is suitable for small and medium-sized wind turbines.

However, there are also some problems with the double-blade design:

The vibration problem of the double-blade design is more serious than that of a single blade, and additional vibration reduction measures need to be taken.

The double-blade design has poor rotational stability and is easily affected by wind changes.

The manufacturing complexity of the double-blade design is higher and the manufacturing process requirements are more stringent. Therefore, the two-blade design is more suitable for small and medium-sized wind turbines, and for large wind turbines, a three-blade design may be more suitable.

3. Advantages of 3-blade design

The 3-blade design is currently the most common solution for wind turbines. It has the following advantages:

The three-blade design has stronger stability and self-balancing capabilities, which is beneficial to improving power generation efficiency and reliability.

The 3-blade design has a more even load distribution and higher structural strength, making it more suitable for large wind turbines. The vibration problem of the 3-blade design is relatively small and does not require excessive vibration reduction measures.

The three-blade design has better rotation stability and can better adapt to complex wind environments.

The manufacturing complexity of the 3-blade design is relatively low, and the manufacturing cost is more advantageous.

Therefore, for large wind turbines, the design of three blades is undoubtedly the best choice. This is also the current mainstream design solution for wind turbines.

4. Technical features of 3-blade design

The reason why the 3-blade design has become mainstream is mainly reflected in the following technical advantages:

Excellent aerodynamic characteristics: The three blades have excellent aerodynamic characteristics, which can capture wind energy to the maximum extent and improve power generation efficiency.

Uniform load distribution: The load distribution of the three blades is relatively uniform, with high structural strength and strong wind resistance.

Simple vibration control: The vibration problem of the 3-blade design is relatively small and does not require excessive vibration reduction measures.

Mature manufacturing process: The manufacturing process of the 3-blade design is relatively simple and the cost is low.

Good self-balancing performance: The 3-blade design has strong self-balancing ability and can better adapt to complex wind environments.

Moderate rotation inertia: The three blades are designed with small rotation inertia, fast response, and can better adapt to wind changes.

In general, the comprehensive technical advantages of the three-blade design make it the best choice for large-scale wind turbines at present. In the future, with the continuous advancement of technology, the design of 4 or more blades may also undergo further development. But in the foreseeable future, 3 blades will still be the mainstream solution for wind turbines.

5. Engineering practice of 3 blade design

In addition to technical advantages, the 3-blade design also has many advantages in practical engineering applications:

Strong structural stability: The structure of the 3-blade design is more stable, can better withstand complex environmental loads, and improves equipment reliability.Simple installation and debugging: The installation and debugging of the 3-blade design is relatively simple, shortening the wind farm construction period.Convenient maintenance: The 3-blade design makes maintenance work relatively easy, extending the service life of the equipment.Low operating costs: The overall operating costs of the 3-blade design are lower, which improves the economic benefits of the wind farm.

Wide adaptability: The 3 blade design can be applied to different types of wind farms and has strong adaptability.

Taking a large domestic wind farm as an example, a 5MW wind turbine unit with a three-blade design has performed well during construction and operation:The overall construction period is shortened by about 20%, which greatly improves the project construction efficiency.The equipment has high reliability and good operational stability, with an average annual utilization of more than 2,500 hours.The operation and maintenance cost is more than 10% lower than that of similar models, which greatly increases project income.It is widely used in different types of wind farms and has strong adaptability.

It can be seen that the three-blade design not only has technical advantages, but also performs well in engineering practice, becoming the mainstream choice for wind turbines.

6. Future development trends

As wind power technology continues to advance, the 3-blade design will continue to be optimized and developed:

Advances in blade materials and manufacturing processes will further improve the performance and reliability of the 3-blade design.The application of intelligent control systems will make the operation of the three blade designs more optimized and efficient.Under the trend of large-scale development, the 3-blade design will develop towards higher-power units, bringing more benefits to wind farms.The integration and application with other new energy technologies will bring new development opportunities to the design of 3 blades.

In general, the 3-blade design has become a mainstream solution for wind turbines due to its excellent technical characteristics and engineering practices, and will continue to be developed and optimized in the future, contributing greater value to the wind power industry.

Leran More:Optimisation of wind turbine blades – ScienceDirect