WIND POWER SOLUTION

ELEGE offers efficient and reliable wind power solutions designed to help customers achieve long-term clean energy use. We provide customized systems that cater to both single turbines and large-scale projects, ensuring optimal energy output and low maintenance costs.

Our wind power systems are built with advanced intelligent control technology, which automatically optimizes performance for maximum efficiency and minimal downtime.

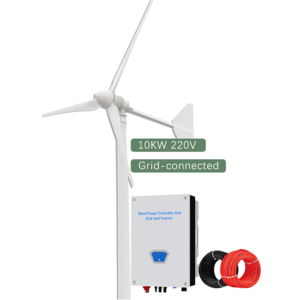

Wind Power System

WIND & SOLAR SOLUTIONS

ELEGE wind-solar hybrid system combines wind and solar energy to provide more stable and efficient clean power. By complementing these two energy sources, our system ensures continuous power supply under various weather conditions, delivering round-the-clock energy.

Whether for residential, commercial, or industrial use, ELEGE wind-solar hybrid system can be customized to meet specific needs. It maximizes the use of both wind and solar energy, ensuring a steady power output even when wind or sunlight is limited.

Wind & Solar System

We’d like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours .

- info@elege.net

- +86-13405295160