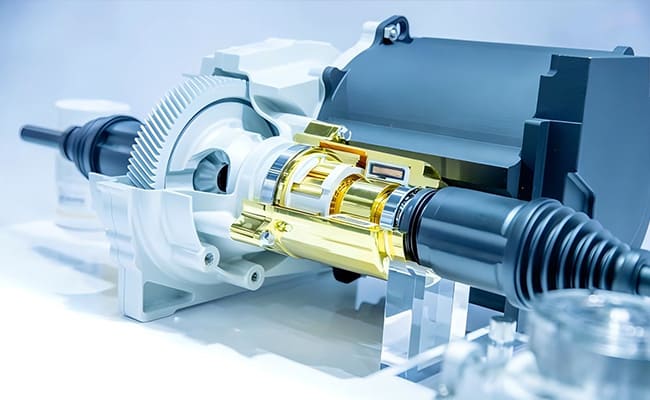

A permanent magnet DC motor (PMDC motor) is a widely used device in various applications, from small generators to electric vehicles. However, like all motors, it can face challenges when it comes to voltage instability. Fluctuating voltages can disrupt its efficient operation, affecting both performance and longevity.

In this blog, we’ll explore practical methods to regulate voltage in permanent magnet DC motors and ensure stable, reliable operation.

🔧 1. Add a Parallel Resistive Load for Stability

One effective way to address voltage instability in a permanent magnet DC motor is by adding a resistive load (such as an incandescent bulb) in parallel with the motor’s field winding. As the bulb heats up, its resistance becomes nonlinear, stabilizing the motor’s excitation curve. This method can help stabilize the operating point at low voltage levels.

✅ Best for: Simple setups where basic components are used to smooth out voltage fluctuations.

🧲 2. Insert Magnetic Shims Under Pole Shoes

By inserting high-permeability magnetic materials (such as soft iron) under the motor’s pole shoes, you can reduce the air gap in the excitation magnetic field. This modification allows the motor’s permanent magnet DC motor to maintain consistent voltage output, even when the load changes.

✅ Best for: Systems where adding electronic components isn’t feasible but stability is still necessary.

⚙️ 3. Use an Automatic Excitation Regulator (AER)

For larger or more complex systems, a generator excitation regulator (AER) can automatically adjust the excitation based on real-time voltage and load conditions. This ensures that the permanent magnet DC motor operates within the optimal voltage range, improving stability and transient response.

✅ Best for: Renewable energy setups or high-load applications requiring advanced voltage control.

💡 Final Tips on Voltage Regulation for DC Motors

When dealing with voltage instability in a DC motor, it’s important to choose the right solution based on the motor’s size, load type, and operating conditions. Whether you opt for simple mechanical modifications or advanced electronic regulation, addressing voltage issues promptly will improve your motor’s efficiency and lifespan.

Key Factors to Consider:

-

The motor’s power level and application

-

Environmental factors (e.g., temperature, humidity)

-

Load behavior (static or dynamic)

A stable permanent magnet DC motor is essential for reliable and efficient operation. By using methods such as adding resistive loads, inserting magnetic shims, or employing an automatic excitation regulator, you can resolve voltage instability and ensure long-term performance. For those working with small wind turbines, electric bikes, or other renewable energy systems, managing voltage fluctuations is key to optimizing system efficiency.