1. The growth of wind turbine power generation in the United States

According to the latest data, U.S. wind energy generation increased by a staggering 27% compared with the same period last year. This huge growth is mainly attributed to the increase in blade length of currently installed wind turbines. This phenomenon and its important reasons will be analyzed in detail below.

As technology continues to advance and innovate, wind turbine design and performance have improved significantly. This increase in blade length, in particular, allows the turbine to capture wind energy more efficiently and convert it into renewable electricity. Longer blades mean the turbine is better able to harness wind energy, producing more electricity even at lower wind speeds. The power generation efficiency is greatly improved.

2. Development of wind turbine blades

The average wind turbine blade used in the 1980s was only 19.81 meters long.

While today’s turbine blades have an average length of 45.72 meters. The blade length is constantly increasing and is expected to exceed 100 meters in the future.

Niketa Kumar said in an article published on the Department of Energy’s website that any new wind turbine technology must undergo the same rigorous testing as he does. With this in mind, the Department of Energy has prepared to invest in testing facilities for wind turbines.

3. The important role of technical testing center

The Wind Technology Test Center in Boston is the first large-scale blade testing base in the United States and can test blades exceeding 90 meters in length. It is located near offshore wind farms and has a 366-metre quay for transporting blades to and from the city centre. The site plays an important role in the wind power industry as turbine blades become larger and larger.

4. Growth trend of wind turbine blade length

Those who know the blade industry may know that in early 2018, the world’s largest wind turbine blade-LM 88.4 P rolled off the assembly line at a factory in Denmark, with a blade length of 88.4 meters.

By 2019, the world’s first wind turbine blade over 100 meters rolled off the assembly line. LM Wind Power’s plant in Cherbourg, France, produced 107-meter-long blades for GE’s Haliade-X12 MW offshore wind turbine. At present, China’s Fujian Fuqing Offshore Wind Power Industrial Park has achieved batch delivery.

On June 27 of the same period, the 10MW B900A blade of Dongfang Electric Wind Power Co., Ltd. rolled off the production line at Tianjin Blade Company. The blade is 90 meters long. However, since 2020, the technological progress of China’s wind power blades has been challenged by the advent of parity, and 100m-class blades have achieved rapid progress.

5. Development of wind power blades in China

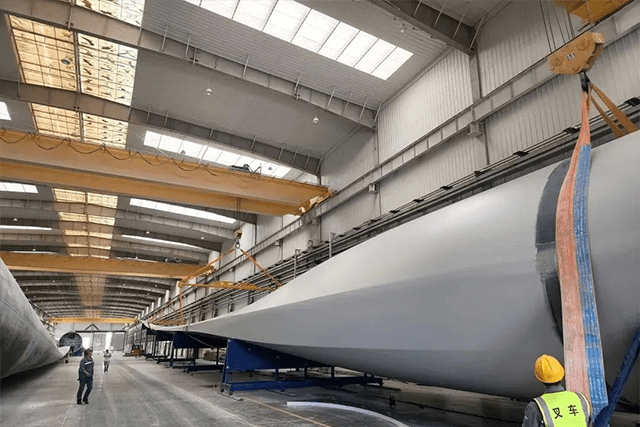

Offshore wind turbine blades with a length of more than 100 meters can be seen everywhere in China’s wind power industry.

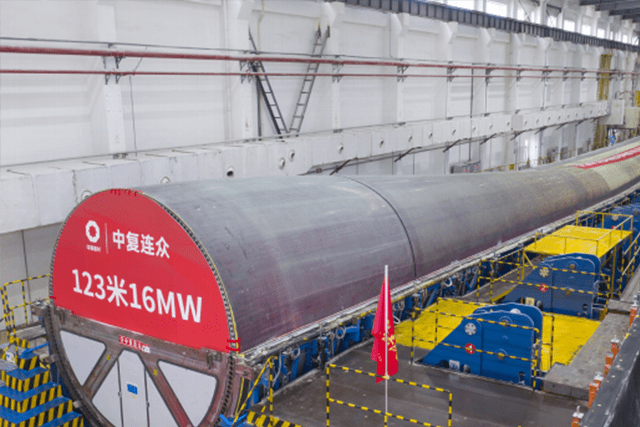

Zhongfu Lianzhong, as one of the leading blade companies in China, has rolled out the fourth blade with a length of more than 100 meters in less than a year, including 102 meters, 110 meters, 112 meters, 123 meters, etc. Blades exceeding 100 meters in length.

6. Shanghai Electric’s trend of independent research and development of blades

September 1: Shanghai Electric’s independently developed 100-meter-plus offshore wind turbine blade S102 was successfully rolled off the production line at Zhongfu Lianzhong in Lianyungang. This is also the first 100-meter-class blade that Shanghai Electric Wind Power has officially entered into offshore wind power.

It should be noted that this blade is Shanghai Electric’s first to adopt new interface fusion technologies such as carbon fiber main beam, blade root prefabrication and trailing edge auxiliary beam prefabrication.

7. The importance and impact of blade quality on the wind power industry

Since 2022, China’s onshore wind power capacity has exceeded 7MW. According to industry statistics, the impeller diameters of leading onshore wind power companies have basically exceeded 200m, including Shanghai Electric, Yunda Co., Ltd., Ming Dynasty Yang Intelligent, Sany Heavy Energy, Goldwind Technology, etc., and some manufacturers’ models have already received orders and will be delivered. Impeller diameters of more than 200m in onshore wind power have become a general trend.

Blades are the core components of the wind turbine and the engine of the wind turbine. Under China’s complex wind conditions and low electricity price market competition, it is particularly important to ensure the reliability and quality of the blades while maintaining low costs.

In history, there are cases where companies have gone bankrupt due to blade reliability and quality problems. It is not uncommon for companies to suffer huge economic losses due to blade design quality and manufacturing quality. And for larger blades, the quality of the blades has been reduced due to reliability problems. The cost will be catastrophic, because if a wind turbine collapses or shuts down due to blade problems, the economic losses will be fatal to the general machine company.