Introduction

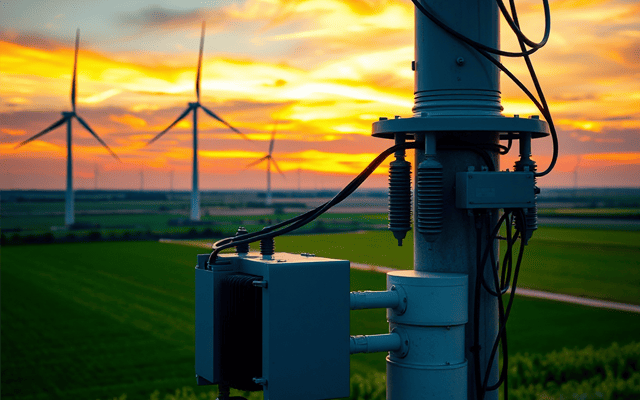

When you picture a wind farm, the first thing that comes to mind is likely a row of turbines gracefully spinning in the breeze. Yet behind that elegant motion lies a powerful electrical backbone — and at the center of it stands the transformer.

Transformers quietly ensure that electricity generated by wind turbines is both usable and stable. Without them, energy could never travel efficiently from the turbine to the power grid or your home. In essence, transformers turn raw wind power into practical, safe electricity.

The Role of Transformers in Wind Power Systems

Wind turbines generate power at relatively low voltages — typically between 690 volts and 1,000 volts. Unfortunately, this level isn’t suitable for long-distance transmission.

To fix this, transformers adjust voltage levels according to system needs. They either step up or step down voltage so that energy moves efficiently through the network. In other words, they act as translators between the turbine’s electrical output and the requirements of the broader power grid.

Moreover, transformers help reduce power losses, stabilize output, and ensure compatibility with different grid systems. Their function is essential for maintaining both energy quality and grid reliability.

Types of Transformers Used in Wind Power

1. Step-Up Transformers

Immediately after energy leaves the turbine’s generator, it passes through a step-up transformer. This unit increases voltage to around 33kV or higher, allowing electricity to travel greater distances with minimal energy loss. Consequently, transmission becomes more efficient and cost-effective.

2. Step-Down Transformers

At the distribution end, step-down transformers perform the opposite task. They lower voltage levels so that electricity can be safely delivered to local users and businesses. These are often found in substations or near grid connection points.

3. Auxiliary Transformers

A wind turbine itself requires power for internal operations — such as control systems, lighting, and yaw motors. Auxiliary transformers handle these smaller internal loads, ensuring the turbine runs smoothly even during maintenance or low-wind conditions.

Transformer Placement in Wind Farms

The positioning of transformers depends on the design and purpose of the turbine.

-

Nacelle-mounted transformers are installed near the generator, which reduces cable losses but makes maintenance more challenging.

-

Tower-base transformers are easier to access and maintain while still minimizing energy loss.

-

Substation transformers, located centrally, collect electricity from several turbines and step up the voltage again before feeding it to the main grid.

Each configuration has trade-offs, balancing efficiency, accessibility, and cost.

Offshore vs. Onshore Transformer Applications

Offshore Transformers

Conditions at sea are unforgiving — salt, moisture, and vibration constantly threaten equipment performance. Therefore, offshore transformers are designed to be compact, sealed, and corrosion-resistant. They must endure tough conditions while remaining reliable for long periods without human intervention.

Onshore Transformers

In contrast, onshore transformers enjoy a more forgiving environment. They can be larger, easier to cool, and simpler to service. Because technicians can access them more easily, onshore systems are often more cost-efficient to operate over time.

Dry-Type vs. Oil-Filled Transformers

The cooling method dramatically affects performance and safety.

-

Dry-type transformers rely on air for cooling. They are safer in areas where fire risk or environmental sensitivity is a concern.

-

Oil-filled transformers, on the other hand, use mineral or synthetic oil for superior insulation and heat dissipation.

Although both types serve their purpose, oil-filled designs are more common in large-scale wind power installations due to their durability and higher efficiency.

The Rise of Smart Transformers

Modern wind farms are getting smarter — and so are their transformers. Many units now feature IoT-based sensors that track parameters like temperature, vibration, and oil quality in real time.

As a result, operators can detect irregularities early, perform predictive maintenance, and prevent costly downtime. Moreover, these smart systems can integrate with SCADA networks, offering greater visibility and data-driven decision-making.

Maintaining Power Quality and Grid Stability

Because wind is naturally unpredictable, wind turbine output can fluctuate rapidly. Transformers help balance these variations, keeping voltage levels stable and reducing electrical noise or harmonics.

In addition, they serve as a protective layer between the intermittent wind supply and the rigid demands of the grid. This ensures a consistent, high-quality power flow that supports everything from industrial equipment to household electronics.

Heat Management and Efficiency

Like all electrical components, transformers generate heat. Managing this heat effectively is crucial for long-term reliability.

Advanced cooling techniques — including forced-air systems, oil circulation, and smart thermal monitoring — prevent overheating. Consequently, these systems not only protect the transformer but also extend its lifespan and efficiency under heavy load conditions.

Maintenance Challenges in Wind Energy Transformers

Wind farms are often located in remote areas, from offshore platforms to mountain ridges. This makes transformer maintenance complex and expensive.

Common issues include:

-

Thermal cycling, caused by fluctuating power loads

-

Moisture contamination, leading to insulation breakdown

-

Mechanical vibration, especially in nacelle-mounted systems

To address these issues, technicians increasingly rely on infrared scanning, oil diagnostics, and remote monitoring to identify faults before they become failures. Preventive care has become the gold standard in modern wind energy operations.

Environmental and Safety Considerations

Transformers must also meet strict environmental standards. Oil leakage or electrical faults can have serious ecological consequences. Therefore, many manufacturers now use biodegradable insulating fluids and fire-resistant materials to reduce risks.

In addition, design improvements — such as compact footprints and sealed casings — minimize the overall environmental impact of transformer installations.

The Future of Transformer Technology in Wind Energy

The next generation of transformers will be smaller, smarter, and more sustainable. Expect to see:

-

Eco-friendly insulating materials replacing traditional oils

-

Integrated sensors with AI-based performance analytics

-

Modular, lightweight designs for hybrid renewable systems

As hybrid solutions — combining wind, solar, and storage — become mainstream, transformers will need to manage multiple power inputs and variable frequencies efficiently. This evolution marks a major step toward fully integrated renewable microgrids.

Why Transformers Deserve More Recognition

While wind turbines capture the spotlight, transformers are the quiet backbone of the industry. They make sure every kilowatt of power travels safely, efficiently, and reliably from remote farms to the grid.

Without these crucial devices, modern renewable energy networks simply wouldn’t function.

Conclusion

Transformers are the hidden heroes of wind energy systems. They don’t produce power, but they make it possible for power to flow where it’s needed — safely and efficiently. As the renewable energy sector expands, transformer innovation will remain at the heart of grid stability and sustainability.

Ultimately, these devices ensure that the promise of clean, reliable wind energy becomes a global reality.

FAQs

1. Why do wind farms use transformers?

They adjust voltage levels to ensure efficient transmission and safe distribution of electricity.

2. What’s the difference between step-up and step-down transformers?

Step-up transformers increase voltage for long-distance transmission, while step-down transformers reduce it for local consumption.

3. How are offshore transformers designed differently?

They’re sealed, compact, and corrosion-resistant to withstand harsh marine environments.

4. What are the benefits of smart transformers?

They enable predictive maintenance, real-time monitoring, and improved grid communication.

5. What’s the next big trend in transformer technology?

Eco-friendly materials, AI-based condition monitoring, and compatibility with hybrid renewable energy systems.