Wind Mill Turbine Overview

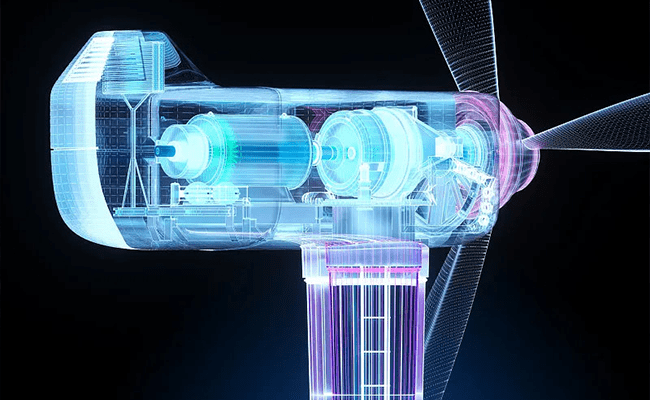

A wind mill turbine converts wind energy into mechanical work. It is also known as a windmill. In a doubly fed turbine, wind spins the blades, increasing speed through the transmission system. Once the generator reaches speed, it produces electricity, converting wind energy into electrical energy. Current technology allows power generation to begin at around 3m/s wind speed.

The wind turbine comprises a base, tower, nacelle, and blades. The tower elevates the turbine and can serve as a transmission line conduit. The nacelle houses generators and control equipment. Blades are crucial components, with their design, materials, and manufacturing processes impacting performance and power output.

1、Sorting out the wind mill turbine industry chain

The wind mill turbine industry chain features three key segments: upstream raw material and component manufacturing, midstream turbine assembly, and downstream wind farm investment and operation. Raw material and component manufacturers form the upstream sector, producing specialized components like gearboxes, generators, bearings, blades, and hubs. Domestic enterprises boast mature technology for these components, with wind turbine manufacturers typically sourcing customized parts from them. Except for key imported bearings, the domestic supply chain for wind turbine components is robust.

Wind turbine manufacturers hold a pivotal industry role with high market concentration, commanding premium prices from suppliers. Downstream clients, notably state-owned power groups, are key investors mandated to support clean energy like wind power.While investment progress may vary annually, the overall demand for wind mill turbines continues to grow steadily.

Profit distribution of the industrial chain (gross profit margin): downstream investment operators > upstream component manufacturers > midstream wind mill turbine manufacturers. At the manufacturing end of the wind mill turbine industry chain, the main shaft, bearings, flanges, cables, and converters have higher gross profit margins, followed by towers and blades. The wind mill turbine assembly stage has the lowest gross profit margin at the manufacturing end, about 16%.

2、System cost and whole machine cost

The average investment cost of offshore wind power is notably higher than that of onshore wind power, approximately twice as much. Offshore wind power construction costs range from $2,100-2,500/KW, while onshore wind power costs range from $700-1,000/KW. In onshore wind power, a significant portion is allocated to wind turbines and towers, with turbines representing 60%, towers and other equipment 15%, and other expenses a smaller share.

In contrast, offshore wind power construction costs are relatively higher. For instance, in Guangdong Province, the total cost breakdown shows wind turbines and towers comprising less than 50%, while wind turbine foundations and installation make up 25%. When facing constraints like limited offshore lifting vessel availability, these costs may escalate further.

Wind power generation costs cover initial project construction investments, operational and maintenance expenses, and financial costs throughout its lifecycle.

Investment cost of wind power generation:

Investment cost encompasses capital expenditure during wind power project development and construction. This includes equipment purchases, construction expenses, installation costs, pre-development and land acquisition expenses, project period interest, and fixed asset depreciation over the project’s lifecycle. Wind power station construction costs are notably high due to complex conditions.

Offshore wind power incurs higher construction costs compared to onshore projects. As per data from the State Grid Energy Research Institute, the average investment cost for offshore wind power stands at roughly double that of onshore wind power.

Onshore wind construction cost:

The current onshore wind power system cost ranges from 700 to 900 US dollars per kilowatt. Construction costs vary based on terrain complexity. In regions with favorable conditions like the northwest’s flat terrain, costs can surpass 700 US dollars per kilowatt. In eastern areas such as Shandong, Hebei, and Shanxi, costs hover around 800 US dollars per kilowatt. Regions like Hunan, Yunnan, Guizhou, and Sichuan, characterized by hilly terrain, see higher costs at about 900 US dollars per kilowatt.

The price of onshore wind turbines typically falls between $280-430 per kilowatt, constituting less than half of the total wind power construction cost.

Offshore wind cost:

Offshore wind power construction costs range from $2,100-2,500/kW, with turbines priced at $850-1,000/kW, accounting for 40% of total costs. In Guangdong, end-2022 costs hit about $2500/kW, with machine body, tower, pile foundation, and submarine cable making up 45%, 27%, and 19% of initial investment. Operational expenses encompass maintenance (48%), loan interest (30%), and taxes (22%).

Blades, gearboxes, and generators are critical and expensive components in wind turbines. In a doubly-fed wind turbine, blades make up 23.58% of costs, followed by the gearbox at 12.66% and generator at 8.65%. Direct-drive generators lack a gearbox but have higher generator costs. Semi-direct drive combines features of both systems.

The wind power industry spans upstream component manufacturing, midstream turbine assembly, and downstream farm operation. Downstream operators reap profits, while machine manufacturers see modest returns. Offshore wind power, with higher construction complexity, costs over twice as much as onshore, with wind turbines and key components like blades, gearboxes, and generators playing crucial roles in cost structures.