In today’s rapidly developing new energy era, various advanced control technologies are emerging. Among them, PWM pulse technology, as an efficient and accurate control method, plays an increasingly important role in the field of new energy. Whether it is solar power generation, wind power generation, or electric vehicles and smart homes, PWM pulse technology plays an indispensable role in them. So, what is PWM pulse technology? How is it applied in the field of new energy? Let’s explore this fascinating world of technology in depth.

1. Definition and principle of PWM pulse technology

PWM, the full name is Pulse Width Modulation, which is translated into Chinese as pulse width modulation. This is a technology that uses the digital output of a microprocessor to control analog circuits. Simply put, PWM controls the duty cycle of power transmission to the load by adjusting the width of a series of pulses, thereby achieving precise control of the load.

PWM pulse technology adjusts output power by varying pulse signal duty cycle. Duty cycle is the high level duration ratio to the entire cycle time. It enables precise control of average output voltage or current, effectively managing load power.

For example, let’s assume we have an LED light and want to control its brightness. Traditional analog methods involve adjusting brightness by changing voltage, leading to inefficiency and heat generation. PWM technology enables precise brightness control by rapidly switching LEDs (at frequencies of several hundred to several thousand hertz). A 100% duty cycle results in maximum brightness, 50% halves brightness, and 0% turns off the LED.

2. Advantages of PWM pulse technology

Compared with traditional analog control methods, PWM pulse technology has many advantages:

High efficiency: PWM technology controls power through fast switching, greatly reducing energy loss and improving the overall efficiency of the system.

Precise control: By adjusting the duty cycle, PWM can achieve precise control of output power with an accuracy of 0.1% or even higher.

Strong anti-interference ability: Since PWM uses digital signals, it is less susceptible to interference from external noise than analog signals.

Easy to implement: Most modern microcontrollers have built-in PWM modules, making the implementation of PWM technology simple and low-cost.

Wide range of applications: PWM technology can be applied to the control of various power electronic equipment, such as motor drive, LED dimming, switching power supply, etc.

3. Application of PWM pulse technology in the field of new energy

With the rapid development of new energy technology, the application of PWM pulse technology in this field is becoming more and more extensive. The following are several typical application scenarios:

Solar power generation system

In the solar power generation system, PWM technology is mainly used to control the solar charge controller. The voltage and current generated by the solar panel will change with the changes in sunlight intensity and temperature. In order to protect the battery and extend its service life, the charging process needs to be precisely controlled. The PWM charge controller can dynamically adjust the size of the charging current according to the charging state of the battery to achieve the best charging effect.

For example, in the early stage of charging, the controller will use a larger duty cycle to allow the battery to charge quickly. As the battery power increases, the controller will gradually reduce the duty cycle, reduce the charging current, and prevent overcharging. This precise control not only improves the charging efficiency, but also effectively extends the service life of the battery.

Wind power generation system

In the wind power generation system, PWM technology is mainly used to control the output power of the wind turbine. Wind speed is constantly changing. In order to maintain the stable operation of the generator and maximize the power generation, the speed of the generator needs to be precisely controlled.

PWM technology enables real-time adjustment of generator load based on wind speed changes, maintaining optimal operation. As wind speed increases, the PWM controller increases load to prevent overspeeding. Conversely, it reduces load when wind speed decreases, ensuring continuous generator operation.This dynamic adjustment not only improves the power generation efficiency, but also enhances the safety of the system.

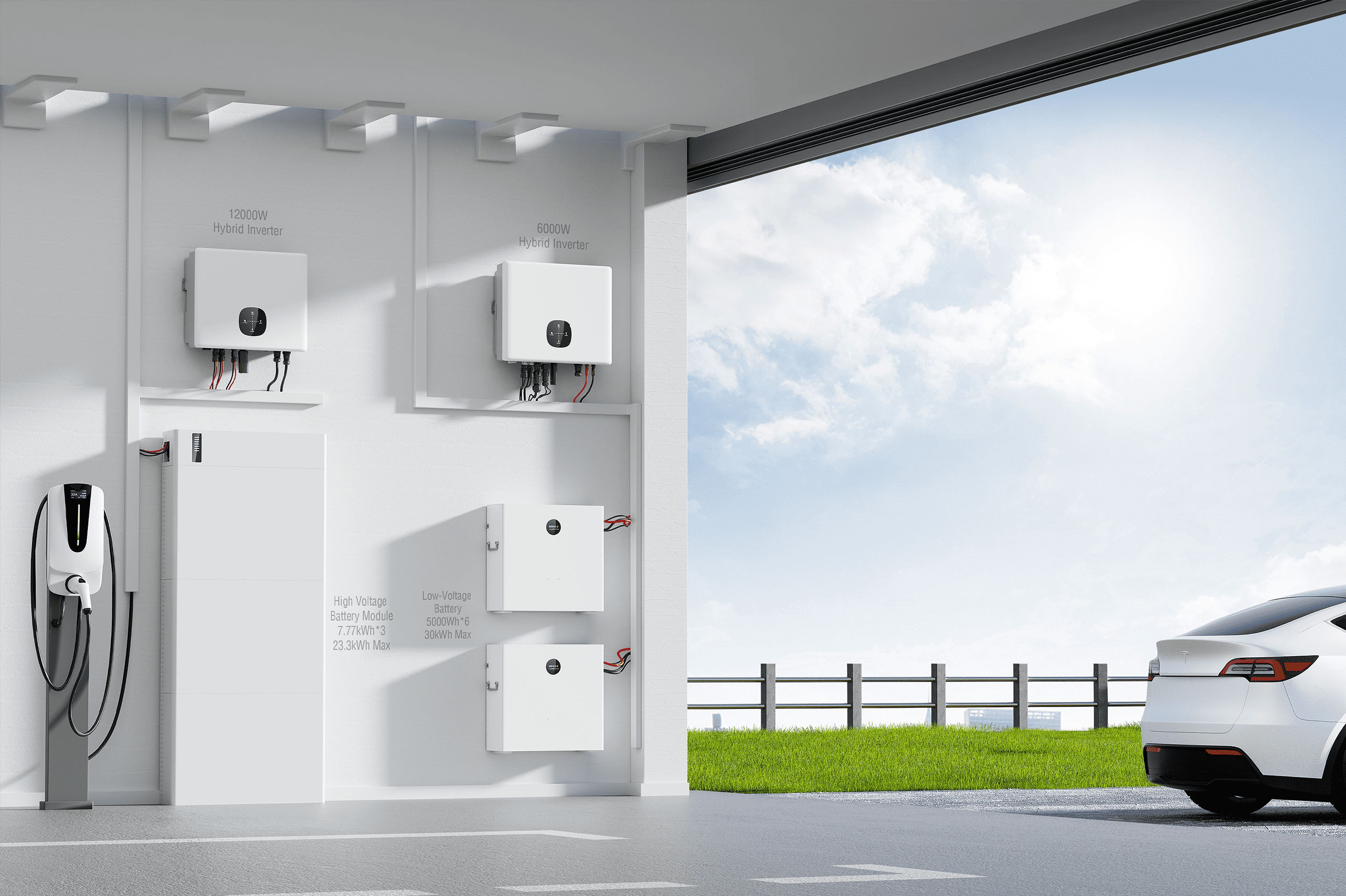

Electric vehicle drive system

In electric vehicles, PWM technology plays a key role in the motor drive system. The motor of an electric vehicle is usually a three-phase AC motor, which needs to be driven by converting DC to AC through an inverter. PWM technology is used to control the switching of the inverter in this process to achieve precise control of the motor speed and torque.

By adjusting the frequency and duty cycle of the PWM signal, the motor can be steplessly adjusted. For example, when the driver steps on the accelerator pedal, the control system increases the duty cycle of the PWM signal and increases the voltage output to the motor, thereby increasing the motor speed and torque. This precise control not only improves the vehicle’s power performance, but also optimizes energy utilization efficiency and extends the battery’s range.

Smart home system

In the field of smart home, PWM technology is widely used in LED lighting control, motor control and other aspects. Taking LED dimming as an example, PWM technology can achieve stepless dimming of LED lights and create a variety of comfortable lighting environments.

In applications such as smart curtains or smart clothes hangers that require precise control of motors, PWM technology also plays an important role. By controlling the speed and torque of the motor through PWM, the smooth opening and closing of curtains or the precise lifting and lowering of clothes hangers can be achieved, improving the user experience.

4. Implementation of PWM pulse technology

To implement PWM pulse technology, there are mainly the following ways:

Hardware PWM

Many modern microcontrollers and single-chip microcomputers have built-in hardware PWM modules. This method uses the timer/counter inside the chip to generate PWM signals, which has the advantages of high precision and low CPU resource consumption. For example, the Arduino platform provides an analogWrite() function that can directly output PWM signals.

Software PWM

In the absence of a hardware PWM module or insufficient hardware PWM channels, PWM can be implemented by software. This method simulates PWM signals by program-controlled high and low level switching of GPIO ports. Although the accuracy and stability are not as good as hardware PWM, it is more flexible and can achieve PWM output on any IO port.

SPWM technology

SPWM (Sinusoidal Pulse Width Modulation) is an advanced application of PWM technology. It generates PWM signals by comparing sine waves with triangle waves, and is mainly used in inverters to convert DC to AC. SPWM technology can significantly reduce the harmonic content of the output voltage and improve the quality of power.

5. Parameter setting of PWM pulse technology

In practical applications, the effect of PWM pulse technology depends largely on the parameter setting. The following are several key parameters:

Frequency

The frequency of the PWM signal determines the speed of the switch. In LED dimming applications, the frequency usually needs to be higher than the flicker frequency that the human eye can perceive (about 100Hz). In motor control, the choice of frequency needs to consider the response characteristics and switching losses of the motor.

Resolution

The resolution determines the accuracy of PWM control. For example, 8-bit resolution can provide 256 levels of adjustment, while 10-bit resolution can provide 1024 levels of adjustment. Higher resolution means more precise control, but also requires higher computing power.

Dead time

In some applications, especially in H-bridge drive circuits, dead time needs to be set to prevent the upper and lower bridge arms from being turned on at the same time and causing a short circuit. Reasonable setting of dead time can improve the reliability and efficiency of the system.

6. Future development trend of PWM pulse technology

With the continuous development of new energy technology and power electronics technology, PWM pulse technology is also evolving. Here are several development trends worth paying attention to:

Digital PWM technology

Traditional PWM technology is mainly based on analog comparator implementation, while digital PWM technology uses digital signal processing (DSP) technology to implement more complex control algorithms, such as adaptive PWM, predictive PWM, etc. This technology can further improve the efficiency and performance of the system.

Multi-level PWM technology

Multi-level PWM technology can significantly improve the output waveform quality and reduce the harmonic content by increasing the output voltage level. This technology is particularly advantageous in high-voltage and high-power applications, such as grid-connected inverters for large wind turbines.

Intelligent PWM control

Combined with artificial intelligence and machine learning technology, PWM control can become more intelligent. For example, in electric vehicles, intelligent PWM controllers can automatically adjust PWM parameters according to driving habits, road conditions and other factors to optimize energy utilization efficiency.

Application of wide bandgap semiconductors in PWM

With the development of wide bandgap semiconductor devices such as SiC (silicon carbide) and GaN (gallium nitride), the application scope of PWM technology will be further expanded. These new devices have the characteristics of high frequency, high temperature and high voltage, which can achieve higher frequency PWM control and further improve system efficiency.

7. Challenges and solutions of PWM pulse technology

Although PWM pulse technology has many advantages, it also faces some challenges in practical applications:

Electromagnetic interference (EMI) problems

High-frequency PWM switching will generate electromagnetic interference and affect nearby electronic devices. Solutions include:

Optimizing PCB layout, minimizing the length and loop area of signal lines

Using EMI filters

Using spread spectrum technology, such as random PWM, to disperse EMI energy

Switching loss

High-frequency PWM switching will lead to increased losses in power devices. Solutions include:

Select high-performance power devices, such as MOSFET or IGBT

Use soft switching technology, such as zero voltage switching (ZVS) or zero current switching (ZCS)

Optimize drive circuit and reduce switching time

Dead zone effect

In full-bridge circuits, in order to prevent direct short circuit, dead zone time needs to be set. However, too long dead zone time will cause output waveform distortion. Solutions include:

Adopt adaptive dead zone control technology

Use intelligent power module (IPM) with built-in dead zone control High-frequency noise

High-frequency PWM may generate audible noise to the human ear, especially in motor control applications. Solutions include: Select appropriate PWM frequency to avoid the sensitive frequency band of the human ear Use random PWM technology to disperse noise energy, optimize mechanical structure design, and reduce resonance

8. Conclusion

PWM pulse technology, as an efficient and precise control method, plays an increasingly important role in the field of new energy. From solar power generation to electric vehicles, from wind power generation to smart homes, PWM technology is everywhere. It not only improves energy utilization efficiency, but also provides the possibility for intelligent control of new energy equipment.

With the continuous advancement of technology, PWM pulse technology will continue to evolve. The emergence of new technologies such as digital PWM, multi-level PWM, and intelligent PWM will further expand the application scope and performance boundaries of PWM. At the same time, combined with advanced technologies such as artificial intelligence and big data, PWM control systems will become more intelligent and efficient.

However, we must also recognize the challenges faced by PWM technology, such as EMI problems and switching losses. These problems require engineers to continue to innovate and solve them through optimizing designs, adopting new materials and new processes. Only in this way can PWM pulse technology play a greater role in the field of new energy and contribute to the sustainable development of mankind.

As people working in the new energy field and people who love technology, we should always pay attention to the development of PWM pulse technology and deeply understand its principles and uses. At the same time, we should also actively try to combine PWM technology with other advanced technologies to explore new application scenarios and innovations. Only in this way can we maintain competitiveness in the rapidly developing new energy field and contribute to the progress of the industry.

learn more:Pulse Width Modulation (PWM) Techniques