1、Unveiling the Power of Permanent Magnet Generators: Structure, Principles, and Applications

The world is rapidly transitioning towards sustainable energy sources, and permanent magnet generators are playing a pivotal role in this revolution. These generators offer high efficiency, compact design, and reliability, making them ideal for a wide range of applications, from wind turbines to electric vehicles. This comprehensive article delves into the intricacies of permanent magnet generators, exploring their structure, working principles, and various classifications.

2、Understanding the Core: How a Permanent Magnet Generator Works

At the heart of a permanent magnet generator lies a fascinating interplay of magnetic fields and motion. Unlike traditional generators that rely on electromagnets, permanent magnet generators utilize the inherent magnetism of permanent magnets to induce electricity. This eliminates the need for external excitation, resulting in higher efficiency and reduced energy losses.

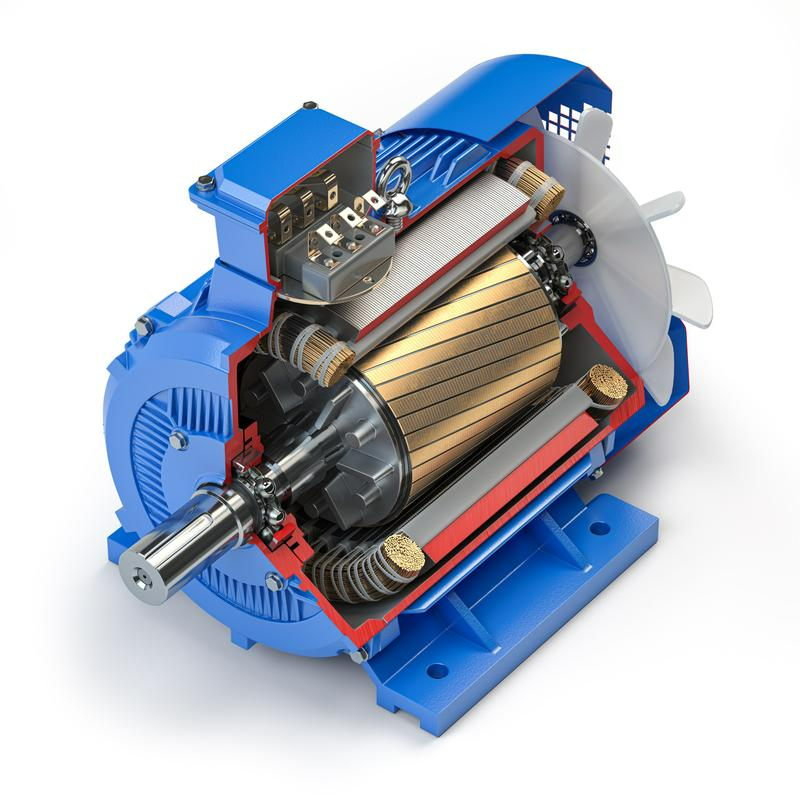

3、The basic components of a permanent magnet generator include:

Rotor: The rotating component typically houses an array of permanent magnets arranged in a specific configuration.

Stator: The stationary component contains coils of wire wound around a core.

Air Gap: The space between the rotor and stator, allowing for smooth rotation and minimizing magnetic losses.

As the rotor spins, the permanent magnets create a rotating magnetic field that cuts through the stator windings.This induces an electromotive force (EMF) in the coils, generating electricity. The frequency and magnitude of the generated voltage depend on the speed of rotation and the strength of the magnetic field.

4、Decoding the Design: Exploring the Structure of Permanent Magnet Generators

Permanent magnet generators come in various designs, each tailored for specific applications.

One common configuration is the disc-type permanent magnet generator, also known as a pancake generator. This design features a flat, disc-shaped rotor with magnets arranged around its circumference. The stator coils are typically positioned on either side of the rotor, maximizing magnetic flux linkage and enhancing power output.

Another popular design is the radial flux permanent magnet generator, where the magnetic flux flows radially outward from the rotor to the stator. This configuration is often used in larger generators due to its inherent robustness and ability to handle higher power levels.

5、 Delving Deeper into Disc-Type Permanent Magnet Generators

Let’s take a closer look at the construction of a disc-type permanent magnet generator:

Rotor Construction:

The rotor typically consists of a non-magnetic core material, such as aluminum or steel, with permanent magnets embedded in its surface. The magnets are strategically positioned to create a rotating magnetic field with a specific number of poles.

Stator Design:

The stator comprises coils of wire wound around a core, forming the armature winding. The number of coils and their arrangement determine the number of phases and the voltage output of the generator.

Material Considerations:

The choice of materials plays a crucial role in the performance and efficiency of the generator. High-strength permanent magnets, such as neodymium magnets, are often preferred due to their powerful magnetic fields.

6、Unveiling the Advantages of Permanent Magnet Alternators

Permanent magnet alternators (PMAs) offer several advantages over traditional alternators:

Higher Efficiency:

PMAs eliminate the need for field excitation, reducing energy losses and improving overall efficiency.

Compact Design:

The absence of field windings allows for a more compact and lightweight design, making PMAs suitable for space-constrained applications.

Improved Reliability:

PMAs have fewer moving parts compared to traditional alternators, reducing the risk of mechanical failure and enhancing reliability.Lower Maintenance: With no brushes or slip rings, PMAs require minimal maintenance, reducing operating costs.

7、Classifying the Powerhouses: Types of Permanent Magnet Generators

Permanent magnet generators can be classified based on various factors, including rotor configuration, number of phases, and application. Some common classifications include:

Synchronous Generators:

These generators operate at a fixed speed determined by the frequency of the power grid. They are commonly used in wind turbines and hydroelectric power plants.

Asynchronous Generators:

Also known as induction generators, these generators operate at a speed slightly higher than the synchronous speed. They are often used in small-scale wind turbines and standalone power systems.

Single-Phase Generators:

These generators produce single-phase AC power and are commonly used in portable generators and residential applications.

Three-Phase Generators:

These generators produce three-phase AC power and are widely used in industrial applications and power grids.

8、The Future of Power Generation: Permanent Magnet Synchronous Generators

Permanent magnet synchronous generators (PMSGs) are gaining significant traction in the renewable energy sector, particularly in wind turbine applications. These generators offer several advantages over traditional induction generators, including:

Higher Efficiency: PMSGs operate at a higher efficiency, especially at low wind speeds, maximizing energy capture and improving overall performance.

Improved Grid Stability: PMSGs offer better grid stability due to their ability to control reactive power. This is crucial for maintaining grid stability and reliability, especially with the increasing integration of renewable energy sources.

Reduced Maintenance: PMSGs require less maintenance compared to induction generators, reducing operating costs and downtime.

9、Exploring Generators with Permanent Magnets: A Closer Look at Applications

Generators with permanent magnets are finding their way into a wide range of applications, transforming the way we generate and utilize power. Some notable examples include:

Wind Turbines:

PMSGs are becoming the preferred choice for large-scale wind turbines due to their high efficiency and grid stability benefits.

Electric Vehicles:

PM generators are used as traction motors in EVs, providing high power density and efficiency for improved performance.

Hybrid Electric Vehicles:

PM generators play a crucial role in HEVs, allowing for regenerative braking and efficient power generation.

Portable Power Generation:

Small-scale PM generators are used in portable power generators, providing a reliable and efficient source of electricity for various applications.

10、Conclusion: Embracing the Power of Permanent Magnets

Permanent magnet generators are revolutionizing the power generation landscape in today’s world. As we pursue cleaner and more efficient energy, permanent magnet generators will play a key role in shaping the new power generation methods of the future. Explore the structure, working principle and application of permanent magnet generators in depth to better understand how they can promote a sustainable and energy-efficient future.

learn more:Permanent-magnet generators